Manufacturing

ARE YOU LOOKING FOR A MANUFACTURER?

Curious about how export-level fabrics elevate your brand’s reputation?

Are you ready to revolutionize your fashion brand with top-tier garment manufacturing? Imagine partnering with a manufacturer who can bring your denim dreams, chino concepts, and cargo creations to life – all with unparalleled quality and flexibility. Welcome to the cutting edge of garment production, where your designs meet our manufacturing expertise. We specialize in crafting premium denim jeans, crisp cotton chinos, and rugged cargo pants that stand out in a crowded market. Our secret? It’s all in the details – from high-quality stitching that withstands the test of time to fabrics that feel as good as they look. But we’re not just about creating clothes; we’re about empowering your brand. Whether you’re a established retailer looking to refresh your line, a wholesaler seeking reliable production, or a startup with a vision to disrupt the industry, we’ve got you covered. We’re more than manufacturers – we’re your partners in fashion innovation. Ready to take the first step towards garment manufacturing excellence? Let’s weave your success story together.

Elevating Style with Expert Craftsmanship: Manufacturing Denim Jeans, Cotton Chinos, and Cargo Pants

Are you tired of compromising on quality or struggling with high minimum order quantities when sourcing denim jeans, cotton chinos, and cargo pants? We’re revolutionizing the apparel industry by offering export-level quality at reasonable rates with minimal MOQs. Whether you’re an online clothing store, a small retailer, or an international buyer, we’ve got you covered.

Imagine being able to offer your customers:

- Custom-designed jeans that fit like a glove

- Chinos crafted from the finest cotton

- Cargo pants that blend style with functionality

All this, without the hefty price tag or the burden of excessive inventory.

At ORBIT, we understand that high-quality apparel starts with expert craftsmanship. Our commitment to excellence in manufacturing ensures that every pair of jeans, chinos, and cargo pants meets the highest standards of export-level quality. And the best part? We offer these premium garments at reasonable rates with minimum order quantities (MOQs) tailored to your needs.

The Craftsmanship Behind Our Denim Jeans

Our manufacturing process begins with sourcing the finest denim fabrics, known for their strength, softness, and ability to age beautifully. We then employ advanced stitching techniques to reinforce key areas like the waistband, pockets, and seams, ensuring that our jeans maintaining their shape and comfort. Whether you prefer a classic straight fit, a modern slim fit, or something in between, we offer a range of designs that can be customized to your specifications. Our low MOQs mean you can create your own line of denim jeans with the assurance that each pair will reflect the quality and craftsmanship that your customers deserve.

Cotton Chinos: Where Comfort Meets Style

Our approach to chino design focuses on creating a garment that meets the demands of the modern man, whether he’s attending a casual wedding or heading to the office. We’ve reimagined chinos to be more than just pants; they’re a fashion statement that bridges the gap between casual and formal wear. Made from lightweight cotton-based materials, our chinos feature partially hidden back pockets and come in various forms and styles to suit different preferences. The use of stretchy cotton fabrics ensures comfort even in slim-fit designs, making them ideal for active lifestyles and travel.One of the key features of our reimagined chinos is their incredible versatility. They can be dressed up or down with ease, making them suitable for a wide range of occasions. Our chinos come in a variety of colors and styles, allowing for endless outfit combinations. From classic pleated design to modern flat-front options, there’s a pair to suit every preference.

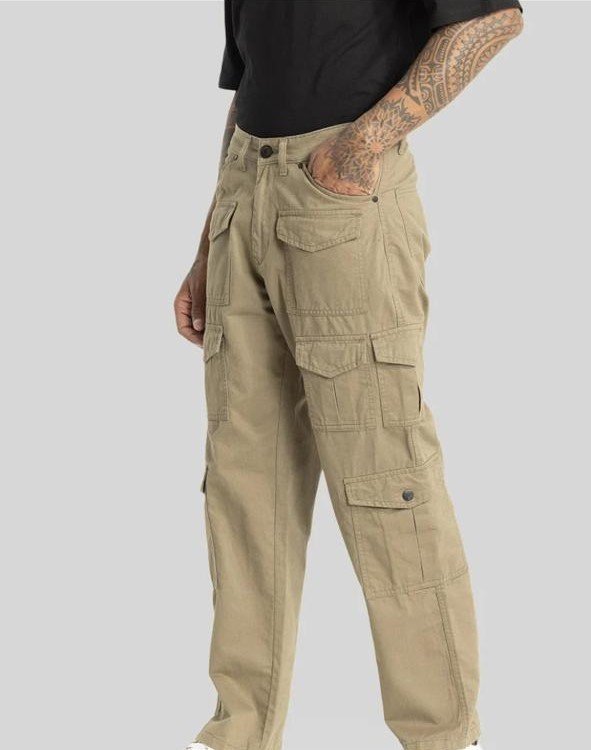

Cargo Pants: Functional Fashion for the Modern Consumer

Cargo pants have made a comeback in recent years, thanks to their blend of style and practicality. Our cargo pants are designed for those who need a bit more from their clothing—extra pockets, reinforced stitching, and fabrics that can handle whatever the day throws at them. Export-quality cargo pants stand out due to their superior construction techniques. The strategic use of stitching plays a crucial role in enhancing both durability and functionality. Key features include:

- Flat-felled seams, known for their strength and durability.

- Reinforced stitching at critical areas like pocket edges and corners.

- Double-needle stitching on pockets, out seams, waist, and inseams.

These techniques not only ensure the longevity of the garment but also contribute to its overall esthetics, reflecting the craftsmanship valued in export-quality products. We use high-quality materials that are both durable and comfortable, ensuring that our cargo pants are ready for any adventure. Whether your customers are looking for a traditional military-inspired look or a more contemporary design, our manufacturing process can accommodate their preferences. And with our low MOQs, you can introduce a range of cargo pants that meet the highest standards of quality without compromising on affordability.

Step-by-Step Guide to our production procedure

Pre-Production Planning

Sourcing Materials and Notions

The first step in garment construction involves sourcing the right materials and notions. This process is crucial for ensuring the quality and durability of the final product. For denim and chinos, manufacturers need to carefully select fabrics, threads, zippers, and other components. It’s essential to create a comprehensive Bill of Materials (BOM) that lists all the raw materials needed to produce the garment and prepare it for shipment . This list typically includes main fabric, secondary fabric (lining), thread, trims, closures, labels, and packaging.

Creating Tech Packs

A Technical Pack, or Tech Pack, serves as the blueprint for the final garment . It’s a set of documents that designers use to communicate their vision to manufacturers, enabling them to transform the information into a finished product. A well-crafted Tech Pack includes detailed flat sketches of the design, materials specifications, measurement specs, size gradings, and colorways. This document is crucial for minimizing errors and bringing products to market faster. It also helps manufacturers gauge production time and costs more accurately.

Cutting Room Procedures

Fabric Spreading Techniques

The cutting room process begins with fabric spreading, a crucial step in garment construction. For denim and chinos, the fabric must be spread carefully on the cutting table. All rolls should be from the same dye lot to ensure consistency in color. The plies of fabric are placed precisely on top of each other, with care taken to mark defects and piece ends.

Marker Making for Efficiency

Marker making is a vital process in optimizing fabric usage and reducing waste. A marker serves as a blueprint containing all design pattern pieces and is used in the cutting process to maximize fabric consumption.

Cutting Methods for Denim and Chinos

The cutting process for denim requires considerable force due to the fabric’s density. There is a limited number of plies that can be cut, regardless of whether the cutting is done manually or with a computer-controlled cutter

Advanced Sewing Techniques

Working with Heavy-Duty Machines

When constructing denim and chinos, our manufacturers often employ heavy-duty machines to handle the thick fabrics. These machines are designed to sew through multiple layers of dense material without jamming or breaking needles. For optimal results, it’s crucial to adjust the machine’s tension and use the appropriate needle size for denim or chino fabric.

Topstitching and Bar Tacking

Topstitching is a key element in elevating the appearance and durability of denim and chinos. It serves both decorative and functional purposes, reinforcing high-stress areas and highlighting style lines. For heavy-duty garments like jeans, topstitching primarily enhances strength and stability. Bar tacking is another crucial technique, utilized at pocket corners and buttonhole edges. It provides durable reinforcement through dense blanket stitches

Applying Rivets and Buttons

The application of rivets and buttons is a defining feature of denim construction. For rivets, manufacturers typically place them along the topstitching where the front pocket meets the leg, at the top corner of the coin pocket, and at the outer corners of the back pockets.

Quality Control Checkpoints

Implementing quality control checkpoints throughout the assembly line is vital for ensuring garment quality.

1. Fabric Inspection

- Check for Defects

- Verify Fabric Weight and Composition

- Color Fastness Testing

2. Pattern and Cutting Accuracy

- Pattern Verification

- Cutting Precision

- Grain Line Alignment

3. Stitching Quality

- Stitch Consistency

- Reinforcement of Stress Points

4. Trims and Embellishments

- Trim Quality Check

- Attachment Security

- Compatibility with Fabric

5. Garment Assembly

- Construction Accuracy

- Symmetry Check

- Fit and Size Verification

6. Finishing and Ironing

- Final Pressing

- Clean Finish

- Labeling and Tagging

7. Final Inspection

- Visual Inspection

- Functional Testing

- Packaging and Presentation

8. Sampling and Batch Testing

- Batch Quality Testing

- Record Keeping

9. Compliance with Safety Standards

- Check for Sharp Objects

- Adherence to Safety Regulations

Why Choose Us?

At ORBIT, we pride ourselves on delivering top-tier manufacturing services that cater to brands looking for high-quality stitching and fabrications. Our export-level quality ensures that your products meet international standards, while our reasonable rates and flexible MOQs make it easier for you to bring your designs to life.

Whether you’re an established brand or a start-up looking to make your mark in the fashion industry, we’re here to help you every step of the way. Partner with us, and let’s create something extraordinary together.

YOUR DESIGNS, OUR MANUFACTURING

If you need further information, kindly contact us:

Email:pakistanorbit@gmail.com and Whatsapp:03166417875

FAQs

Cotton is commonly used in cargo pants due to its durability.

Cargo pants are primarily made from cotton-based materials such as cotton itself, polyester, and sometimes fleece, each chosen for its specific properties and uses.

Our minimum order quantity (MOQ) varies depending on the type of garment and customization requirements. We offer flexible MOQs to accommodate both small and large orders, ensuring that you get the best value for your investment.

Yes, we offer full customization services. You can specify the design, fit, fabric, stitching details, and even branding elements like labels and tags. We work closely with you to bring your vision to life.

Quality is our top priority. We implement stringent quality control checks at every stage of production, from fabric inspection to final garment assembly. Our process includes pattern verification, stitching checks, and a final inspection to ensure that every piece meets our high standards.

Yes, we offer sample production to help you evaluate the quality, fit, and design before proceeding with full-scale manufacturing. This allows you to make any necessary adjustments and ensures that the final product meets your expectations.

Absolutely! We provide private labeling services, allowing you to manufacture garments under your brand’s name. We handle everything from label design to application, ensuring a seamless integration with your brand identity.

Our pricing is competitive and depends on factors such as the type of garment, fabric choice, order quantity, and customization options. We offer transparent pricing with no hidden costs and work with you to find the best solution for your budget.